Bring Life to Your Living Space

If you’re planning a roof repair or patching job, knowing how long roofing tar takes to dry is critical for successful results. Roofing tar typically takes 8 to 24 hours to dry to the touch, but it can require 48 to 72 hours or even longer to fully cure depending on weather conditions. Understanding the difference between “dry to touch” and “fully cured” can save you from costly mistakes, premature damage, and failed repairs. In this complete guide, we’ll break down exact drying timelines, factors that affect curing, and expert tips to ensure your roofing tar sets properly before rain or foot traffic.

What Is Roofing Tar and Where Is It Used?

Roofing tar, also called roof cement or bitumen sealant, is a thick, sticky, waterproof substance made from petroleum byproducts. It’s designed to create a durable, weather-resistant seal on roofs. Roofing tar comes in two main forms: cold-applied (ready to use straight from the container) and hot-applied (requires heating before application).

Common uses for roofing tar include:

- Sealing roof leaks and cracks

- Securing flashing around chimneys, vents, and skylights

- Patching damaged shingles or flat roof membranes

- Coating and waterproofing flat or low-slope roofs

- Emergency repairs before permanent fixes

Roofing tar is popular because it’s affordable, easy to apply, and provides excellent waterproofing. However, its effectiveness depends heavily on proper drying and curing time.

How Long Does Roofing Tar Take to Dry? (Quick Answer)

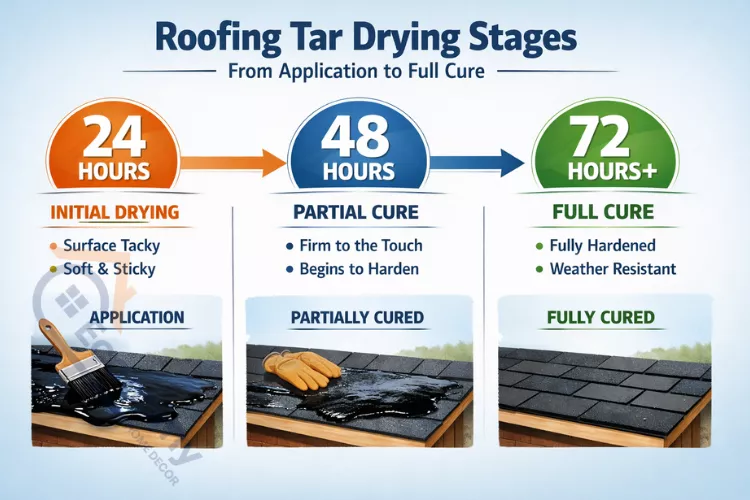

Here’s a quick breakdown of roofing tar drying stages:

- Dry to touch: 8 to 24 hours (surface feels dry but not fully hardened)

- Walk-on safe: 24 to 48 hours (light foot traffic possible with caution)

- Fully cured: 48 to 72 hours minimum, up to 30 days for complete hardening

Keep in mind that these are general estimates. Actual drying time varies based on temperature, humidity, application thickness, and tar type. Always check the manufacturer’s instructions for specific guidance.

Roofing Tar Drying Time Breakdown

| Condition | Time Range | Notes |

|---|---|---|

| Dry to Touch | 8–24 hours | Surface layer hardens; still soft underneath |

| Light Foot Traffic | 24–48 hours | Can walk carefully; avoid heavy pressure |

| Rain-Resistant | 24–48 hours | Can withstand light rain; heavy rain not recommended |

| Fully Cured | 48–72 hours | Minimum for complete waterproofing |

| Maximum Hardness | 7–30 days | Full chemical cure; maximum durability achieved |

Pro tip: Even if tar feels dry after 24 hours, it’s still vulnerable. Always wait at least 48 hours before exposing it to rain or heavy use.

Factors That Affect Roofing Tar Drying Time

Several environmental and application factors determine how quickly roofing tar dries:

1. Weather Temperature

Temperature is the biggest factor. Roofing tar dries fastest in warm conditions:

- Ideal range: 70°F to 85°F (21°C to 29°C)

- Slow drying: Below 50°F (10°C)

- Very slow/won’t cure properly: Below 40°F (4°C)

Hot weather accelerates drying, but extreme heat (above 95°F) can cause uneven curing or surface bubbling.

2. Humidity Levels

High humidity slows evaporation and extends drying time significantly:

- Low humidity (below 50%): Faster drying

- High humidity (above 70%): Can double drying time

- Rainy or foggy conditions: May prevent proper curing altogether

3. Sun Exposure

Direct sunlight helps roofing tar cure faster by warming the surface and promoting evaporation. Shaded areas or north-facing roofs may take 50% longer to dry compared to sunny sections.

4. Thickness of Application

Thicker layers take exponentially longer to dry:

- Thin coat (⅛ inch): 8–12 hours to touch-dry

- Medium coat (¼ inch): 18–24 hours

- Thick coat (½ inch or more): 48+ hours, may crack if applied too thick

Always apply roofing tar in thin, even layers for best results.

5. Type and Brand of Tar

Different formulations have different drying times:

- Standard asphalt tar: 24–48 hours

- Quick-dry formulas: 8–12 hours

- Fiber-reinforced tar: 36–72 hours (thicker consistency)

- Rubberized tar: 24–36 hours

Always read product labels for manufacturer-specific drying times.

Can Roofing Tar Dry in Cold or Humid Weather?

Yes, but with significant limitations. Roofing tar can technically dry in less-than-ideal conditions, but the results may be compromised.

Cold Weather Risks:

- Below 50°F: Drying slows dramatically; may take 3–5 days

- Below 40°F: Tar becomes too stiff to apply properly and may never fully cure

- Risk of cracking, poor adhesion, and reduced waterproofing

Humid Weather Risks:

- Moisture in the air prevents proper evaporation

- Can lead to tacky surfaces that collect dirt and debris

- May cause blistering or peeling once weather changes

Ideal Temperature Range: 60°F to 85°F with humidity below 60%

Seasonal Tips:

- Spring/Fall: Check weather forecasts carefully; apply during warmest part of day

- Summer: Best season for roofing tar; avoid extreme heat days

- Winter: Only apply as emergency repair; consider alternative sealants designed for cold weather

If you must apply tar in marginal conditions, choose quick-dry formulas and apply the thinnest possible coat.

How Long Should Roofing Tar Dry Before Rain?

Minimum safe time: 24 to 48 hours of dry weather after application.

Ideally, you want 48 to 72 hours before any rainfall. This ensures the tar has progressed beyond the surface-dry stage and won’t wash away or become compromised.

What Happens If It Rains Too Soon:

- Within 4–8 hours: Tar may wash away completely, requiring reapplication

- Within 12–24 hours: Surface may become uneven, tacky, or develop water pockets

- After 24 hours: Minor rain usually won’t cause major damage, but heavy downpours can still affect curing

- After 48+ hours: Tar should withstand normal rainfall without issues

Emergency Tips If Rain Is Coming:

- Check hourly weather forecasts before starting any tar work

- Apply in morning to maximize drying time before afternoon storms

- Use quick-dry formulas if rain is expected within 48 hours

- Cover with tarps if unexpected rain threatens (only if tar is somewhat set)

- Reschedule the job if heavy rain is forecast within 36 hours

Pro tip: Never gamble with weather. One rainstorm can undo hours of work and waste materials.

Roofing Tar vs Roof Coating Dry Time

Different roofing products have vastly different drying characteristics:

| Product Type | Dry to Touch | Walk-On Safe | Fully Cured | Best For |

|---|---|---|---|---|

| Roofing Tar (Asphalt) | 8–24 hours | 24–48 hours | 48–72 hours | Patching, flashing, emergency repairs |

| Acrylic Coating | 4–6 hours | 12–24 hours | 24–48 hours | Reflective coating, flat roofs, cooler climates |

| Silicone Coating | 1–2 hours | 6–12 hours | 24–36 hours | Ponding water areas, extreme weather resistance |

| Polyurethane Coating | 8–12 hours | 24–36 hours | 48–96 hours | High-traffic roofs, superior durability |

Key Differences:

- Roofing tar is thicker and takes longer to cure but provides excellent waterproofing

- Acrylic coatings dry faster and reflect heat but aren’t as durable in ponding water

- Silicone coatings offer the fastest drying time and best weather resistance but cost more

- Polyurethane provides maximum durability but requires the longest cure time

Choose based on your specific needs, timeline, and budget.

Tips to Make Roofing Tar Dry Faster (Safely)

While you can’t rush the chemical curing process, these strategies help optimize drying time:

1. Prepare the Surface Properly

- Clean roof thoroughly; remove dirt, debris, and loose materials

- Dry surface completely before application (no dew or moisture)

- Prime porous surfaces for better adhesion and faster setting

2. Apply Thin, Even Layers

- Use ⅛ to ¼ inch thickness maximum

- Multiple thin coats are better than one thick application

- Allow each coat to dry before adding another

3. Choose the Best Time of Day

- Best: Mid-morning (9 AM–11 AM) on sunny days

- Good: Early afternoon if no rain forecast

- Avoid: Late afternoon, evening, or when dew is expected

4. Maximize Sun Exposure

- Work on sunny days with temperatures between 70°F–85°F

- Start on south-facing sections that get maximum sunlight

- Avoid shaded areas until weather is optimal

5. Improve Ventilation

- On flat roofs, ensure air can circulate

- Don’t trap moisture under tarps or covers

- Keep roof area open to air movement

6. Use Quick-Dry Formulas

- Invest in premium quick-dry roofing tar for time-sensitive projects

- These typically dry 30–50% faster than standard products

What NOT to Do:

- Never use fans, heaters, or torches to “speed dry” tar (fire hazard and can damage the seal)

- Don’t apply in direct extreme heat above 95°F (can cause blistering)

- Avoid working in windy conditions that blow debris onto wet tar

Common Mistakes to Avoid

Even experienced DIYers make these critical errors:

1. Applying Tar Too Thick

Thick applications don’t dry evenly. The surface may feel dry while underneath remains soft, leading to cracks, uneven curing, and premature failure. Always apply multiple thin coats instead of one thick layer.

2. Ignoring the Weather Forecast

Checking only the day-of weather isn’t enough. Review the 48-hour forecast minimum before starting. One unexpected rainstorm can ruin your entire job.

3. Walking on Tar Too Early

Even if the surface feels dry after 12–18 hours, it’s still soft underneath. Walking on it can leave permanent impressions, compromise the seal, and reduce lifespan. Wait the full 24–48 hours.

4. Skipping Surface Preparation

Applying tar to dirty, wet, or oily surfaces prevents proper adhesion. The tar may peel away within weeks. Always clean and dry thoroughly first.

5. Using Expired or Low-Quality Products

Old tar becomes too thick or separates, leading to uneven drying and poor performance. Buy from reputable suppliers and check expiration dates.

6. Applying in Wrong Temperatures

Cold weather application is one of the most common mistakes. If the temperature is below 50°F, reschedule or use cold-weather alternatives.

Frequently Asked Questions

Wait at least 24 to 48 hours before walking on roofing tar. While the surface may feel dry after 12–18 hours, the tar underneath is still soft and vulnerable. Walking too soon can leave permanent footprints, compromise the waterproof seal, and reduce durability. For heavy traffic or equipment, wait a minimum of 72 hours.

No, roofing tar is not waterproof when still wet or uncured. It needs time to harden and form a proper seal. If rain hits fresh tar within the first 8–12 hours, it can wash away or prevent proper curing. Always wait at least 24–48 hours of dry weather after application before any rain exposure for reliable waterproofing.

You can apply roofing tar in winter only if temperatures stay consistently above 50°F (10°C) during application and for 48 hours afterward. Below 40°F, tar becomes too stiff, won’t adhere properly, and may never fully cure. For cold-weather repairs, consider specialized cold-applied sealants or rubberized products designed for winter use.

When properly applied and fully cured, roofing tar typically lasts 10 to 20 years depending on climate, sun exposure, and roof traffic. In harsh conditions (extreme heat, UV exposure, ponding water), lifespan may reduce to 5–10 years. Regular maintenance and recoating every 5–7 years extends longevity significantly.

Roofing tar is considered a semi-permanent solution, not a permanent fix. It’s excellent for emergency repairs, patching small leaks, and sealing flashing, but it’s not a substitute for proper roof replacement or major structural repairs. For small issues, tar can last 10+ years. For temporary fixes, plan for a more permanent solution within 1–3 years.

In optimal conditions (75°F+, low humidity, thin application), roofing tar can become touch-dry overnight (8–12 hours). However, it won’t be fully cured or safe for foot traffic. “Dry overnight” means surface-level drying only. Always allow 24–48 hours minimum before considering the repair complete or exposing it to stress.

If roofing tar doesn’t dry properly due to cold weather, humidity, or thick application, it remains tacky, collects dirt, may never fully harden, and can peel or crack prematurely. The waterproof seal will be compromised, allowing leaks. If tar stays wet-looking after 48 hours in good weather, scrape it off and reapply correctly.

Conclusion

Understanding how long roofing tar takes to dry is essential for successful roof repairs. While tar typically becomes touch-dry within 8 to 24 hours, full curing requires 48 to 72 hours or more depending on weather conditions, application thickness, and product type. Always plan for at least 48 hours of dry weather after application, apply thin coats, work in temperatures between 60°F–85°F, and avoid walking on the surface prematurely. By following these expert guidelines and avoiding common mistakes, you’ll ensure your roofing tar dries properly, creates a lasting waterproof seal, and protects your roof for years to come.